Safety is the first priority in production

Intercom Communications – Seek help immediately in case of emergency

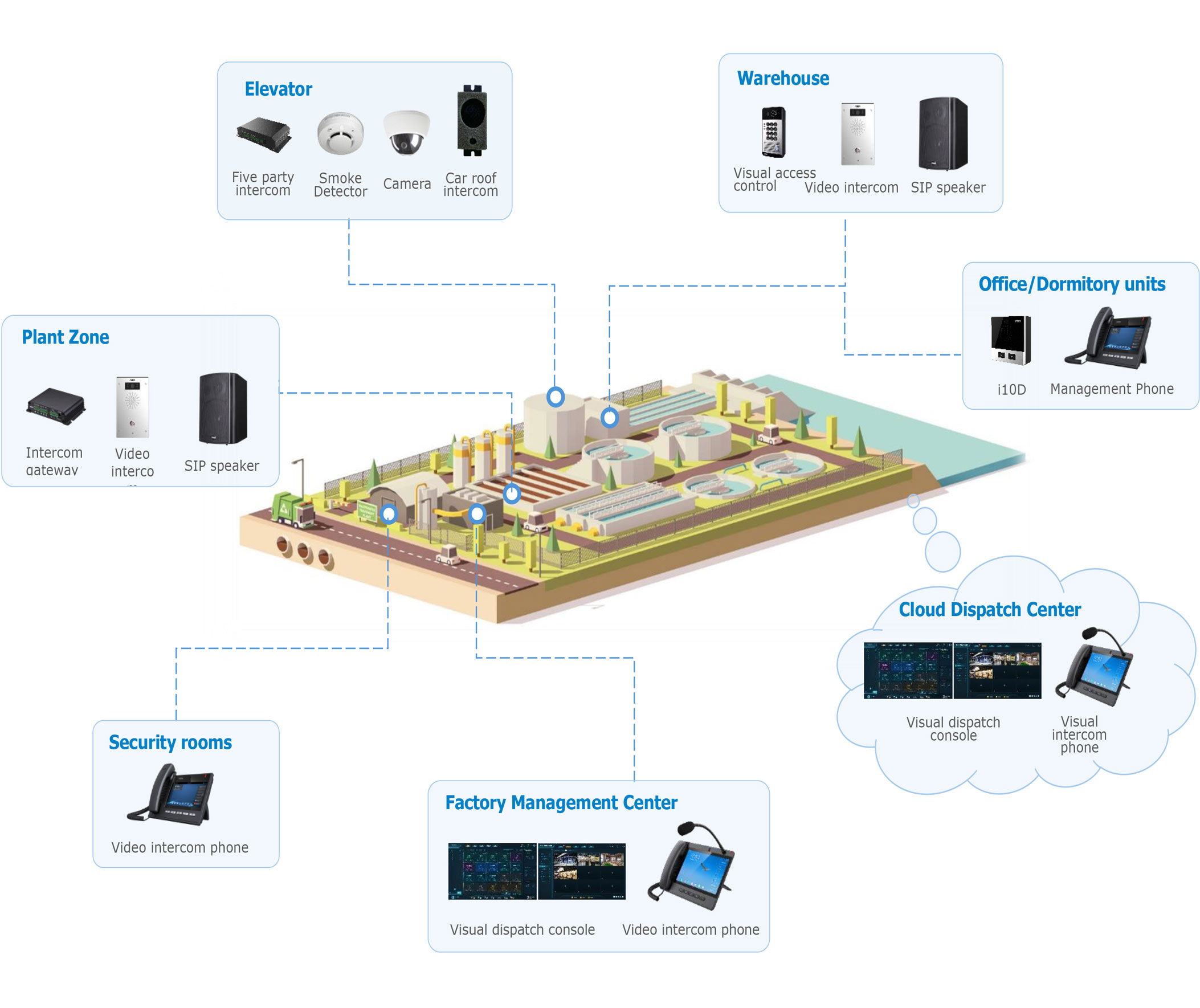

–Intercom Point are widely available throughout the manufacturing plant

–One button direct connection

–Ability to call up a nearby camera

–HD Voice communication between the Intercom Point and management office

Sending notification to specific zone

For large factories, covering a wide area, a fully functional broadcast system is needed to deliver various messages.

–Emergency evacuation broadcast covering the entire factory

–Scheduled broadcast to and from get off work

–Sending working instruction to workers in different zone.

Phone system

Empower entire plant to stay connected at all times from production site to office , from the workers to managers.

High quality voice talk for daily communication.

Quick start the video conference between different departments.